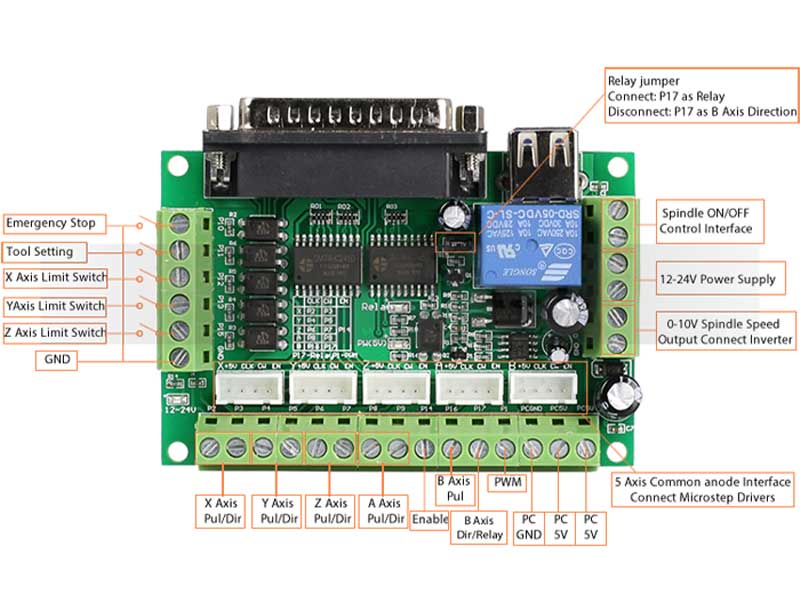

Axis drives (Axis Drives) are a type of motor driver used in CNC (computer numerical control) machines. These drivers control axis motors for motion control in CNC machines.

Axis drivers are often used with servo motors or stepper motors. These motors are specially designed to provide accurate and precise motion control.

Axis drivers provide motion control, usually using PID (Proportional-Integral-Derivative) control systems. These control systems continuously monitor engine speed and position to move the engine quickly and accurately towards the target location.

Axis drivers can control multiple motors running on different axes to increase the mobility of the machines. For example, on a CNC lathe, three separate axis drivers can be used for the x, y, and z axes.

Axis drives are available in many different form factors and capacities. These are selected to suit the movement requirements of the machines. In addition, some axis drives offer parameters that can be adjusted via the appropriate software, so they can be customized to suit different motion profiles of machines.

Axis drivers are a critical component in motion control of CNC machines. Choosing the right axis drive is important to ensure accurate and precise motion control of machines.

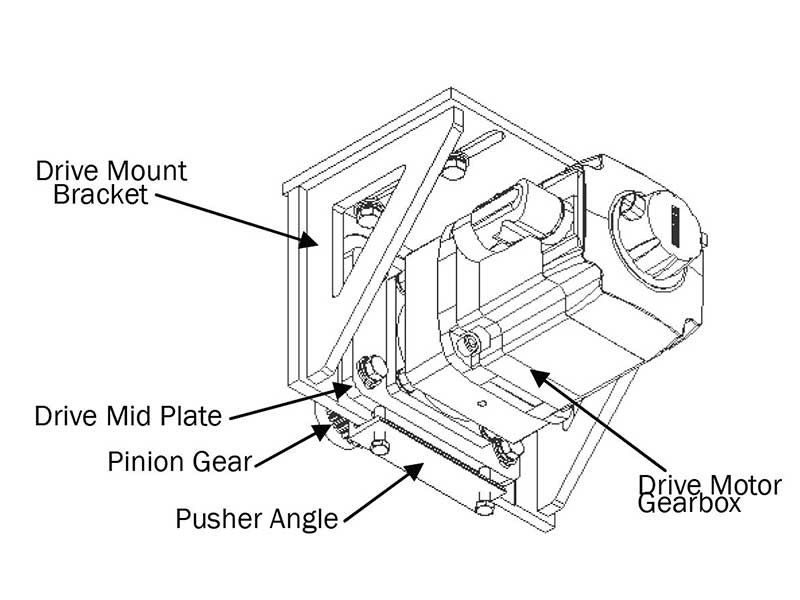

A spindle is a component used in CNC (computer numerical control) machines and is usually designed as a spindle rotating at high speeds. This component performs the machining operation by holding the cutting tools.

Spindle can be designed in different ways for different types of machines. For example, in CNC lathes, the spindle is usually in a fixed position and allows the cutting tools to rotate on the workpiece. In CNC milling machines, the spindle is designed as a spindle that can move on the workpiece at different angles.

It consists of several components such as spindle, motor and bearing. The motor provides the power that makes the spindle rotate. The spindle bearing accurately supports the spindle, allowing it to rotate at high speeds and also provides cooling to prevent overheating.

The spindle's rotation speed is usually expressed in RPM (revolutions per minute). Different rotational speeds are required for different machining operations, so the spindle speed can be adjusted via software.

Spindle provides an interface that can hold many different cutting tools. These cutting tools can be of different shapes and sizes, such as milling cutters, drill bits or drill bits. On CNC machines, cutting tools are often changed via an automatic tool changer.

For example, a CNC milling machine can machine different materials using different cutting tools. These cutting tools can be changed automatically via a tool changer on the spindle. In this way, higher flexibility and efficiency are achieved in the cutting operations of the machines.

Spindle is an essential component for the machining process in CNC machines. Choosing the right spindle is important for the machines to perform accurate and precise machining operations. In addition, the use of additional components such as automatic tool changer is important to increase the efficiency of the machines.